Acoustic hovering is becoming an increasingly present and useful technical reality, and has gained a variety of applications as the science is understood and the resource optimized.

In August, at the SIGGRAPH (Special Interest Group on Interactive Graphics and Technologies) conference in Vancouver, Canada, an international team of researchers will present LeviPrint, their innovative project consisting of a system that uses voice manipulation to assemble objects without physical contact. .

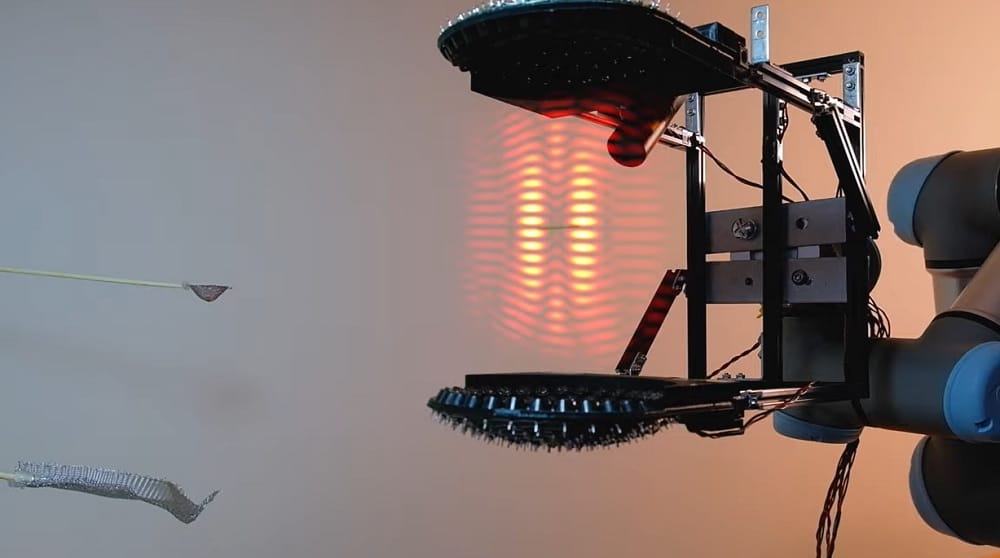

Developed by scientists from the Public University of Navarra (NUP) in Spain, Ultraleap Ltd in the UK and the University of São Paulo in Brazil, the system generates acoustic fields that trap small particles, glue droplets and stick-like elements that can be manipulated and redirected as they rise. According to the site TechxploreIt is a fully functional system for fabricating 3D structures using non-contact manipulation.

Unlike traditional assembly and manufacturing techniques, where the parts are in direct contact with the machine, acoustic processing has been used to position and orient the parts without touching them during the assembly process.

“We can handle small, brittle parts, as well as liquids or powders, making the processes more versatile,” said Inigo Iscordia, a doctoral student at NUP and lead author of the research. “There is less cross-contamination because the processor does not touch the material. Additionally, it enables manufacturing techniques that cannot be achieved with traditional 3D printing, such as adding items to existing parts or manufacturing inside containers that are sealed from the outside.”

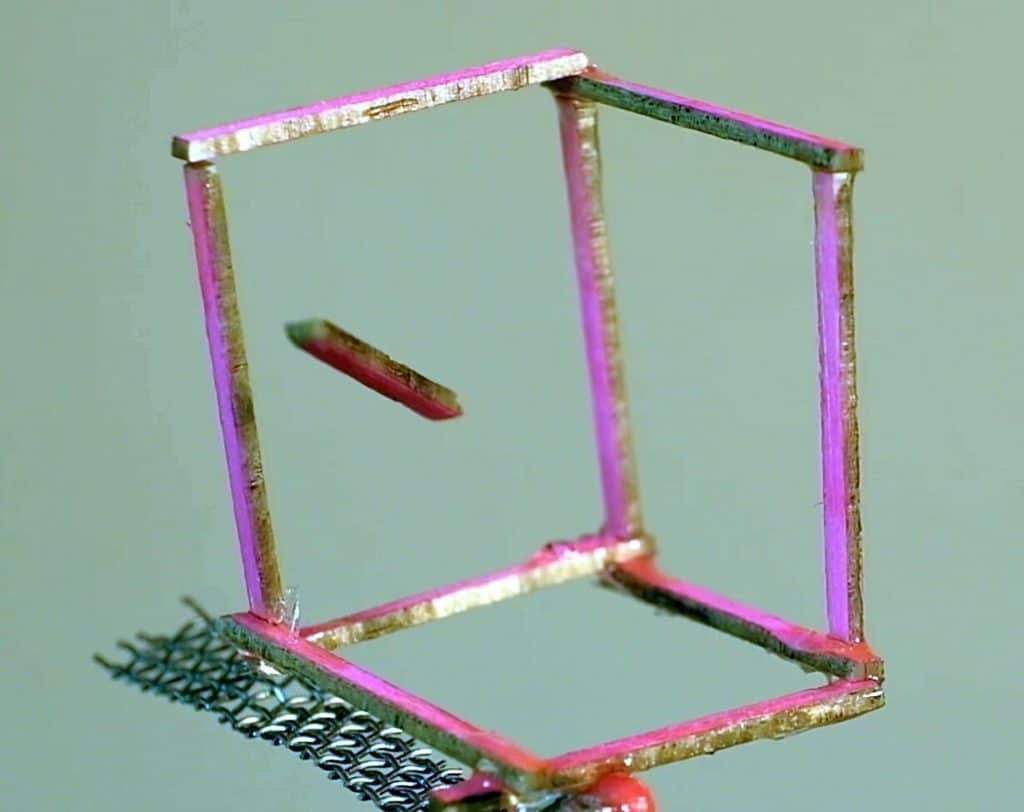

According to Ezcurdia, small particles and droplets have been lifted before, but no current work has been successful in stabilizing elongated objects in position and direction. “This research makes it possible to use strips, sticks, or beams for the rapid, non-contact fabrication of strong, light, and complex structures.”

Some of the techniques presented include the use of glue that freezes with ultraviolet light. The system uses sonic levitation to trap a drop of glue that is dispensed by a syringe, which is raised to the position where the next piece will be added. The system takes a piece or particle, places it next to the previous parts in contact with the glue, and uses ultraviolet light to cure the glue so that the new piece attaches to the structure.

According to the project’s authors, if the Leviprint is adapted to operate in an aqueous medium, the system can synthesize complex structures in cell culture and possibly even within living organisms.

Have you seen our new videos on Youtube? Subscribe to our channel!

“Proud thinker. Tv fanatic. Communicator. Evil student. Food junkie. Passionate coffee geek. Award-winning alcohol advocate.”